How one of Denmark’s leading manufacturer is using machine learning automated quality assurance

A customer success story about quality assurance in manufacturing

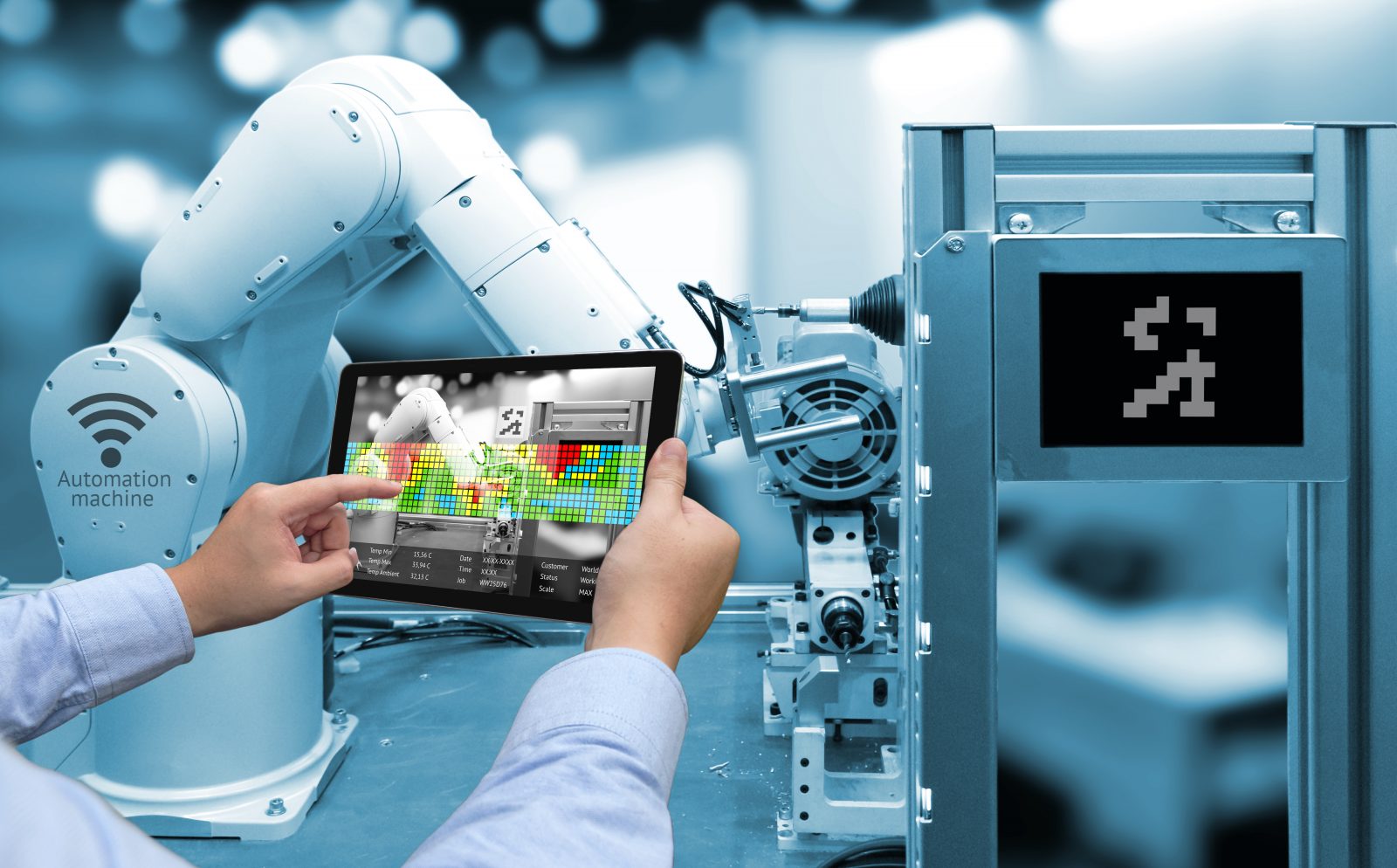

Artificial intelligence (AI) and machine learning (ML) are now transforming every industry.

Their use has become particularly widespread in quality assurance and there are countless good reasons for that. Apart from the substantial fact that machine learning enhanced quality assurance is more accurate, among the other benefits are:

- Reduction of test maintenance and labor costs

- Optimization of supply chain and security

- Effective processing and real-time product insights

- Enhanced workplace safety

Especially in manufacturing, automated quality assurance is making a huge difference in visual inspection and issue identification. Both represent a challenge that require intensive human labor but significantly less so with ML.

Join us for a 1:1 session!

At Trifork we are experts in automated quality assurance for manufacturing. Join our experts for a unique 1:1 session together with your team and hear how we have helped one of the biggest manufacturers in Denmark apply automated visual inspection at scale. Become inspired by our business cases with a focus on KPIs and learn from Trifork how ML can be applied to your quality assurance strategy.

The session will cover:

- How automated quality assurance has helped one of Denmark’s biggest manufacturing companies reduce their error rate in production

- Demo videos from a number of cases

- The main gains and business cases behind automated quality assurance

- Steps to implement ML automated quality assurance

To book your session or any related inquiries please reach out to us.

-

Line Christa Amanda Sørensen

International

-

Rasmus Bisgaard

Esbjerg

Subscribe

Find out the latest news first

Content