Case

Customer

Royal Unibrew

Industry

Food and Beverages

The challenge

Royal Unibrew, a leading European multi beverage producer and distributor company, faced fragmented warehouse operations across regions:

Both regions required a solution tailored to their unique workflows, pain points, and user requirements. The challenge was clear:

The solution

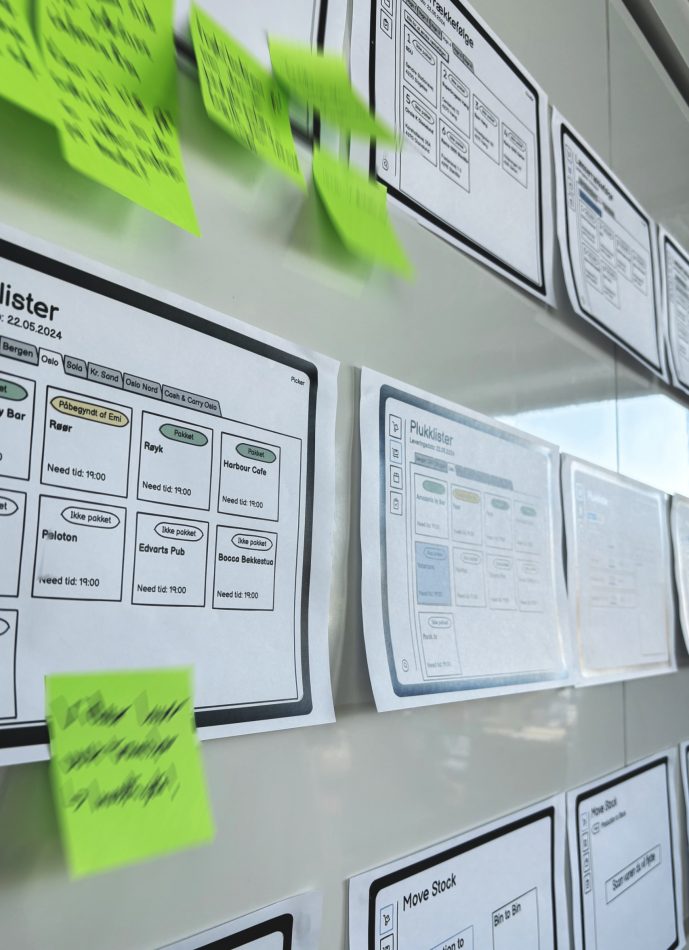

Royal Unibrew partnered with Trifork to co-create a custom mobile application that supports end-to-end warehouse processes of different plants — from inbound to outbound, including receiving, storing, picking, packing, and moving goods.

“The value has been clear. We’ve gained structure, traceability, and accuracy. We’ve reduced human error and made the lives of our warehouse teams easier. Internally, we just call it “the Trifork solution”, and we’re already discussing how to build on it further.”

Jack Madsen

Director Enterprise Applications and Technology, Royal Unibrew

Our approach

Key outcomes

Royal Unibrew selected Trifork for our:

One Mobile App driving operations for 9 warehouses across the Nordics and growing, benefiting +130 users.

Real-time interaction with SAP ECC and S/4HANA upgrade compatibility by following SAP Clean Core principles.

Successfully navigating a dynamic scope, strong inter-dependencies, and summer holiday slowdowns.

End-to-end warehouse process coverage — inbound, internal, outbound.

Contact us

If you prefer, you can also contact us on info@trifork.com

Subscribe

Find out the latest news first

Content