Case

Customer

Vestas

Industry

Sustainable Energy

Vestas Wind Systems A/S is the energy industry’s global partner on sustainable energy solutions. They design, manufacture, install, and service wind turbines across the globe with local presence in 83 countries.

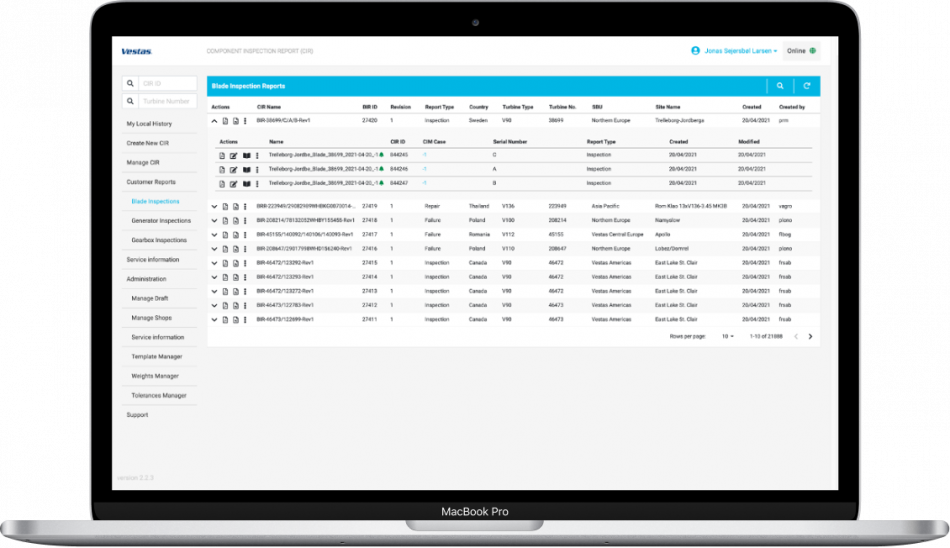

Once installed, the wind turbines are often enrolled in the Vestas service business for annual inspections, general maintenance, and repairs. To ensure proper documentation of their inspections, Vestas’ 10.000 field service technicians use Component Inspection Reporting (CIR), a .net web-based system developed by an engine partner.

To keep up with the growing number of turbines under Service, Vestas needed to improve the performance and extend the capabilities of the CIR system. Beyond the basic performance of the system, efficiencies like automated 3rd party inspection integration, field service notifications, and AI evaluations were needed to maintain high quality reporting.

Strategically, the CIR project is of great importance to us. We are thrilled to see that our new system is well received by our field service technicians and engineering teams. With Trifork as our trusted partners, we have succeeded in creating a valuable digital tool.

Prodromos Palamidis

Director, Global Head of Turbine Operations Engineering

Vestas opted to work with Trifork to solve their CIR system challenge. Thorough analyses of the existing CIR platform showed that Vestas would be unable to add the required functionality to the system.

Based on Trifork’s recommendation, Vestas decided to rewrite the backend and frontend of the CIR system to create an updated tech platform that meets the user requirements and allows for seamless release of new functionality within CIR.

Initially, the new platform was launched into production with the same feature set as the old CIR platform. Once the performance was verified, Vestas and Trifork were able to start releasing new features to widen the scope and improve the functionality of the system.

1st release: New and user-friendly template for repairs.

2nd release: Integration to AI engine that optimizes the damage reporting process.

3rd release: Drone API, enabling integration from all drone provider systems into CIR.

4th release: Template Manager, create and change templates in a few, easy steps.

5th release: OEM – supplier access to CIR.

The updated CIR system is the perfect example of the Trifork core offering: Inspire, Build and Run. By taking operations into account from the beginning of the project, Vestas identified the great business case associated with a stable, flexible and well-performing CIR system. This has created a system that is capable of working with the extensive volume and variety of data that is captured through Vestas’ service activities, and significantly reduces the time spent by technicians and engineers using the system.

With a rewritten CIR front- and backend, Vestas has achieved optimal performance by investing in the right architecture, enabling them to release a continuous stream of new and improved features that meet the needs of their users – the 10.000 field service technicians.

The new and improved CIR system provides the ability to quickly add features and functionalities to our field service platform. This stream of continuous development and optimization adds true business value to our organization.

Prodromos Palamidis

Director, Global Head of Turbine Operations Engineering

The CIR backend is developed using an event-driven architecture with a focus on well-defined APIs to allow for stable integration and utilization of other systems. The backend is built on Azure and with a keen eye on the runtime cost utilizing technologies such as EventHub, Blobstorage and Azure Functions.

For the frontend, one of the primary technical drivers was to develop an application that can handle hundreds of high-resolution images in an offline environment where you often do not have an internet connection. This was solved by building a web application that can run offline and, in the background, synchronizes the data to the backend once internet connection becomes available. Technologies such as Angular, SignalR and form.io were used to accomplish this

Subscribe

Find out the latest news first

Content