Case

Customer

Royal Greenland

Industry

Fishing

The Challenge

Quality control is the process of validating whether a product or service meets the expected delivery standards. Today, many industries do quality control by hand, and that’s the case for Royal Greenland’s frozen prawn product lineup.

While highly methodical, their manual quality process comes with significant challenges:

The outcome is introducing variability for a process that requires consistency and reliability. The challenge was clear:

The Solution

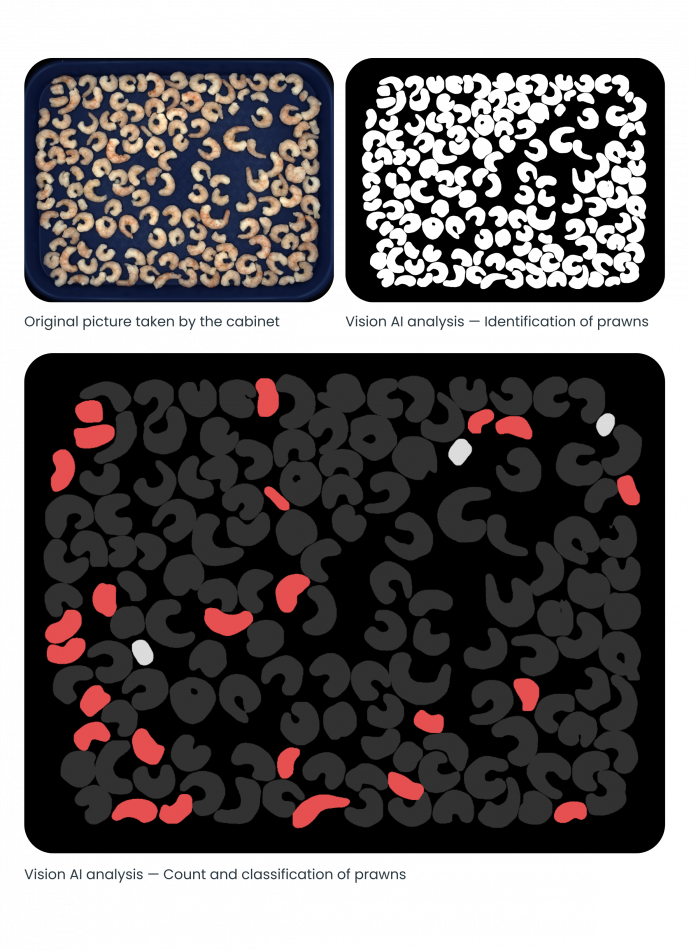

Solving the challenge needed to build a system that captures prawn samples as pictures in controlled environmental conditions, analyzes them under the same evaluation criteria, and presents the results in an easy and friendly way. To do it, we merged three different factors:

All combined results in an end-to-end quality control system that helps lab technicians remove guesswork and makes analysis results transparent, uniform, and trusted.

Our approach

The Outcome

While the product is in its early stages, preliminary outcomes are highly promising.

Custom-trained Vision AI model for detecting visual defects in seafood batches.

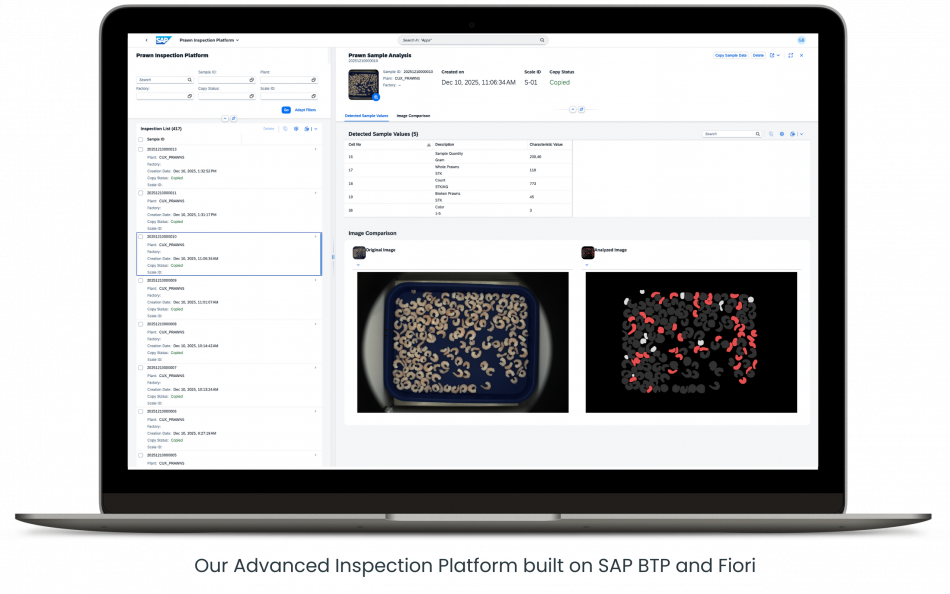

AI results presented through a SAP-native UX tailored for lab technicians.

Application conceptualized as a reusable product running on SAP Business Technology Platform.

If you prefer, you can also contact us on info@trifork.com

Subscribe

Find out the latest news first

Content